Broaching machines and modern manufacturing

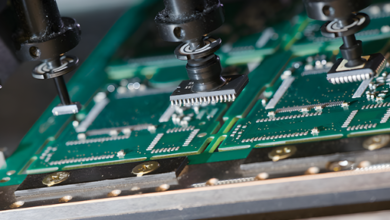

In the realm of precision and efficiency in metalworking, broaching machines hold significant importance. They are designed to remove material with remarkable accuracy, enabling the creation of complex shapes and intricately machined parts.

For those aiming to advance their manufacturing processes, broaching machines offer a pathway to improved productivity.

STENHOJ Hydraulik has established a global reputation in the automotive industry by offering high-performance, customizable broaching machines. These machines incorporate cutting-edge electro-mechanical and automation technologies to meet a wide range of industrial needs.

Choosing machinery from a respected manufacturer provides a balance of reliability and innovation.

For companies looking to enhance their operations, broaching machines combine advanced engineering with practical utility. Particularly in sectors like automotive or any industry requiring precise manufacturing, understanding these machines aids in making informed decisions about their incorporation into production lines.

Expertise in manufacturing

Stenhoj Hydraulik, acknowledged in the automotive industry, brings over twenty years of experience in crafting high-performance broaching machines and presses. Each machine is customizable to fit specific industrial requirements, ensuring the equipment aligns with individual needs.

The integration of advanced electro-mechanical and automation technologies is central to Stenhoj Hydraulik’s innovative strategy. These technologies enhance efficiency and precision, providing machines that deliver consistent performance.

Key features include:

- Customizable designs

- High-performance efficiency

- Integration of advanced automation

For industries seeking to improve productivity and precision, Stenhoj Hydraulik’s machines are an excellent choice. Their emphasis on quality ensures dependable service from each machine.

Stenhoj Hydraulik remains a trusted partner for companies worldwide, delivering solutions that meet diverse industrial needs and guarantee optimal performance.

Designing high-performance broaching machines

Customization is crucial for creating high-performance broaching machines that meet varied industrial requirements. Considering your industry’s specific needs and applications is essential for developing effective solutions.

Working with reputable entities like STENHOJ Hydraulik allows for the integration of advanced electro-mechanical and automation technologies.

For peak performance, prioritize durable construction. Use innovative materials and engineering techniques to handle high-volume production demands.

Precision at every stage is essential for achieving the desired outcomes.

Efficiency and automation are key aspects in modern broaching machine design, enhancing production and minimizing downtime. Broaching machines require meticulous attention for optimal design and performance.

Customization and innovation in manufacturing

Focusing on customization and innovation allows for advanced technologies tailored to specific industrial needs. Electro-mechanical and automation advancements enhance flexibility and efficiency, aligning with industry demands.

Broaching machines are utilizing sophisticated electro-mechanical components that boost precision and reliability. Computer numerical control (CNC) systems provide more precise control over the broaching process, improving quality and reducing waste.

Moreover, smart sensors and feedback systems offer real-time monitoring and adjustments, ensuring optimal efficiency and reduced maintenance needs. Variable frequency drives (VFDs) improve performance through adaptable speed controls, increasing productivity.

By incorporating robotics and automated material handling systems, production is streamlined, reducing labor costs and increasing throughput. Automated inspection and quality control ensure consistent output standards without manual intervention. AI and machine learning further optimize processes.

Addressing diverse industrial needs

With evolving industrial requirements, machinery versatility is essential. Broaching machines offer flexible solutions by handling various materials and complex shapes. Customization allows industries to adjust specifications to fit unique operational needs.

Incorporating advanced electro-mechanical and automation technologies ensures precise and efficient operations. Enhancements in electrical systems improve adaptability and precision, establishing new production benchmarks.

Companies like STENHOJ Hydraulik excel in developing high-performance systems that seamlessly integrate into varied industrial settings.

Broaching machines effectively serve automotive manufacturing, metalworking, and aerospace applications. Their precision and repeatability minimize waste and enhance efficiency, showcasing a dedication to innovative engineering and adapting to customer demands.

Integrating with existing systems minimizes disruption and maximizes productivity. Broaching machines adapt to challenges, maintaining a competitive edge across industries.

Increasing productivity is essential for future readiness, and broaching machines play a pivotal role in meeting modern demands.