When most customers imagine the difficult part of a steel project, they think about the process leading up to receiving a size and quote for a design that they can then approve. In the physical world, the most challenging part involves trying to anticipate how that building will be used every day, and then designing a space that can accommodate that routine without friction.

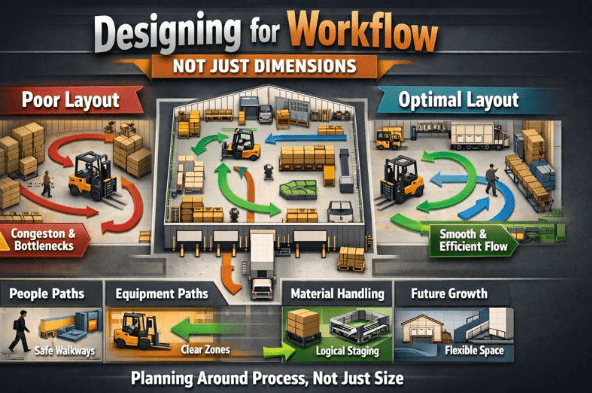

I discovered this early on when working on layouts for small manufacturers and service businesses that were “upgrading” to larger space. On paper, the square footage seemed right. In reality, forklifts crimped corners, staging areas obstructed doors and employees added extra steps to their days continuously because the flow of activity was never shuttled into a system. A steel building can go up quickly and inexpensively, but only if it’s designed around the way people, products and equipment move.

If you request us to give you a phenomenal framework, over 1.6 GB in size, that will still allow for your real-world steel building and also teach you how that works AND exactly where it should work (in daily operation not just dimension), you can learn more about real world steel building applications before finalizing your layout and workflow decisions.

The Design in Workflow Should Come First

A steel building is a kit, not a container. The framing, openings, slab, envelope and mechanical systems are either aligned to support your process or they create little bottlenecks that become permanent headaches.

Start With Movement, Not Measurements

That will help you decide on a width and length. Inquire where materials come in, where they sit and wait, where they get processed, and where they leave.

The best designs for commercial steel buildings should run “quietly,” as traffic flows smoothly. The worst ones feel cluttered even when production is business as usual, as everything cuts across.

People Paths Separated From Equipment Paths

The most costly errors in a safety zone within numerous industrial type steel buildings are accidents and incidents. Productivity suffers and risk increases when pedestrian walkways, forklifts, pallet jacks and traffic are forced to congregate in the same tight aisles.

Some involve elements of design (clear zones, predictable intersections and turning radius so that equipment doesn’t fight the building), but common sense plays a major role.

Have the Building Defend Your Availability

Other aspects of the workflow include cleaning, maintenance and service access. If you rely on a lift, a crane or a specific machine clearance as part of your daily routine, the building has to secure that for decades.

That’s the reason, steel building package system should be considered as a practicable instrument and not simply like a construction offer.

Steel Buildings’ Applications That Rely on How You Run Them

The uses of steel buildings are wide and varied, but the most successful projects have one thing in common: the building complements the job.

Warehousing and Logistics

Warehouses are not just storage. They are movement and timing.

Racking and aisle width depends on column spacing. Pallet density and equipment type are influenced by eave height. Dock locations influence truck stacking and yard movements. If the building makes trailers load up in a very un-C-shaped queue, you will “pay rent” on that decision every day in lost time.

For logistics-intensive steel building uses, it’s building around receiving and shipping patterns rather than a “generic” footprint.

Manufacturing and Light Industrial

Manufacturing SOPs generally require specified areas: receiving, staging, production, quality, packaging and finished goods/outbound. Even a slight change in the placement of doors or distance between bays can make it easier or more challenging to design the entire line.

In the real projects I have reviewed, owners are frequently underestimating support requirements such as compressed air runs, power drops, ventilation and future machine swaps. Industrial steel buildings shine best when the building can adapt to change and is adaptable.

Service Bays and Commercial Operations

Auto service, equipment repair and contractor shops are traditional commercial steel buildings because they require good clearances, wide doors and interiors that can stand the wear and tear of tools.

Workflow is everything here. If there’s a lot of back-and-chinese-finger-trap action getting a vehicle in, turned around and out, productivity suffers.

This is where steel building solutions really stand out when design acknowledges the nitty-gritty of everyday life; several doors, usable bay depth, protected client parking and a clearly defined demarcation between publics spaces and ones work place.

Agriculture, Processing, and Storage

Steel Structure Building in Agriculture: The applications of this steel structure are equipment storage, processing areas, etc. The problem with the workflow is generally simply seasonal intensity. A layout that felt “fine” when planned can get crowded at harvest time.

These chores are then easier with flexible space, easy access for oversized equipment and a building envelope that is opted for moisture, wash-down or temperature control contingent on use.

Community, Municipal, and Specialty Facilities

Municipal storage buildings, fire stations, sports complexes and training centers have selected steel time and again because clear spans matter and a long life is expected.

The work is informed by how long it takes to respond to a public circulating event. Where the arrangement makes such routines possible, steel becomes not a friction but a long-run asset.

Steel Building Applications That Impact Cost, Comfort and Quality

Buildings that are the same size in square footage can cost wildly differently, because it’s “use” that drives engineering, components and labor.

Clear Spans, Height and Interior Adaptability

Clear span designs minimise internal obstructions that support racking, assembly lines and event space. Height provides stacking, crane and ventilation capabilities.

Both are valuable when they coincide with the workflow, both of those are waste if selected there is primarily a marketing appeal.

Doors, Docks, and Openings

Big holes affect structural design and how much you’ll pay for the installation too, of course, but also day to day performance.

A single overhead door off the mark can induce awkward backings, extra staging time and perpetual congestion. If rapid turnover is key to your operation, where doors go is not a detail. It’s a workflow choice with a price tag.

Loads, Codes, and Site Conditions

Factors like wind, snow, seismic requirements and local code can all change steel weight and engineering. Site conditions impact the design of the slabs, drainage and access.

Both types of steel building systems should take these into consideration early on, so you’re not in store for as many surprises later.

Envelope and Insulation Choices

Comfort is a workflow too. When employees are battling heat, cold, condensation or glare, productivity falls and maintenance climbs.

Roof and wall assemblies, insulation type, vapor control and ventilation have to be consistent with operation particularly for conditioned commercial steel buildings or humidity-sensitive storage such as food stock.

Commercial Steel Buildings Vs Industrial Steel Buildings

The terms are to some extent synonymous, although the operational levels and requirements do not entirely overlap.

And what it reveals is that customer experience can be put second to the commercial desire.

Commercial Needs Often Include Public-Facing Flow

Steel office buildings for businesses could require completed office spaces and clean public-facing entries, in addition to aesthetically attractive facades and a tastefully engineered acoustic environment.

The flow incorporates visitor flow, signage visibility, and delivery access deterring visitors.

Industrial Priorities Focus on Durability and Process Support

When it comes to industry, it’s all about durability and process support.

In the case of commercial steel buildings superior clearances, powerful units, quality ventilation, dust control and attractive finishes are most important. The process scheme is linked with bottling, material handling and production constraints.

For these types of facilities, “good enough” design can become costly very fast.

How to Select the Perfect Steel Building Solution for Your Workflow

A trustworthy decision procedure is not based on a catalogue. It starts with your day.

Describe a Day-in-the-Life Scenario

Tell a story that reads like your busiest day. Where does the lead truck turn? Where do materials land? Which steps repeat. Where do people walk most?

This story triggers bottlenecks before steel is even ordered.

Plan the Building Around Those Bottlenecks

As soon as you identify the pinch points, you can make selective decisions: reconfigure bay spacing, move docks, add door width, raise where necessary, shield areas for staging or separating traffic paths.

These are pre-engineered metal building solutions that create real operational wins.

Providing for Growth That Will Not Interrupt Service

Expansion planning is not just “leave room on the lot. It’s also plotting where structural lines, endwall locations and utilities are so an addition can attach seamlessly.

In a lot of steel building instances, you have the ability to expand should you need it for future growth or E-commerce without having to reintroduce workflow.

Evaluate Partners, Not Just Prices

Steel construction applications are, of course numerous and no one manufacturer or installer is top in all areas.

Inquire about how they approach permitting, engineering, delivery sequencing and field issues. Again, the cheapest quote is not a steal when your deliverable is stunted by hasty design and weak coordination.

Common Mistakes I See in Steel Projects and Workflows

The most common failure is designing from the outside in, owners choose a footprint rather than figure out how operations should be structured.

Underestimating available staging space is another common mistake. And many spaces function as such only so long as aisles, doorways and corners are used for storage until life is slowly strangled.

I also see buildings built for today’s equipment, without consideration for larger forklifts, extra racking or a future line. Steel is flexible, but it’s a lot less expensive to design flexibility into things than it is to retrofit around unnecessary constraints.

Summary: Design for the Job, Not the Drawing

It comes down to how well the steel building serves real life applications: traffic flow, daily uses, safety and performance (your must have scenarios), as well as staging for future growth after you move in.

If you pick your buildings based on your workflow, commercial steel structures give it a feeling of efficiency and peace, and industrial steel buildings are flexible for however you change the operations.

If you only take away one key component from this guide, let it be that: the proper steel building solution is the one that decreases resistance within your logistical flow every day, and the portion of the equation which eliminates friction points is never the part that looks good on paper.

FAQs

What are popular steel building uses at present?

Uses: Popular for commercial and industrial applications, such as warehouses, distribution centers, production facilities and service bays (among many others), steel buildings are practical and simple to build. These are popular because steel works for wide spans, fast construction schedules and plant layouts that can be adjusted as operations change.

In what ways does the purpose of construction impact design more than size?

Steel building function establishes where doors need to be placed, clearance issues, interior load requirements, ventilation needs, insulation levels and traffic flow. It doesn’t take a very large difference in area to have two spaces perform completely differently if one is designed for flowing receiving and staging and the other is built with constant cross-traffic and congestion.

Can I use commercial steel buildings for businesses that are customer facing?

Yes, commercial steel buildings can function effectively for retail-adjacent operations or service centers, showrooms combined with warehousing space and mixed-use spaces. The trick is to design so that customer “flow,” sight lines, acoustics, and a welcoming conditioned space don’t compromise the vital work area in the back.

How do I select the right manufacturing steel building solutions?

Pay attention to the flow of work, clearance around equipment, utilities paths, ventilation capacity and room for expansion. Industrial steel structures work well if they plan for machine upgrades, maintenance access and the actual movement of materials on the floor.

What are the potential workflow issues for me to avoid when we break ground?

Map your busiest day, from the moment you leave home to when you fall asleep, and try your design on that reality. Confirm all turning radii, staging areas, dock locations, pedestrian access routes and plans for future expansion. This is the easiest way to avoid expensive layout regret later.