Introduction

Facing rising costs, higher precision demands, and supply chain instability, traditional manufacturing struggles with inefficiency. The core limitation is human-dependent processes, which cause errors and waste. This article presents CNC turning technology applied to brass precision components as an automated solution for production optimization and significant cost reduction, enhancing manufacturing competitiveness.

How Does CNC Turning Drive Efficiency in the Manufacturing Business?

The digital transformation of global manufacturing is an undeniable megatrend. The International Organization for Standardization (ISO) identifies automation and digital integration as crucial for enhancing resilience and efficiency in the manufacturing business. As a cornerstone of modern CNC industry trends, CNC turning meets these demands by translating digital designs into precise instructions for automated lathes, eliminating the variability of manual processes.

This automation delivers measurable productivity gains. The application of CNC machine brass technology exemplifies this, leveraging the material’s excellent machinability. Companies using CNC turning for complex brass parts report over 20% efficiency increases and significant improvements in consistency, representing a revolution in process predictability.

These efficiency gains require a quality foundation. Adherence to internationally recognized standards like ISO 9001 provides a framework for systematizing the CNC machining process. This ensures technical benefits are institutionalized, allowing a business to build a reputation for reliable quality while scaling efficiency, creating a natural transition to cost control.

Why Have Brass Precision Turned Parts Become the Preferred Choice for the Aerospace Industry?

The aerospace industry imposes some of the most demanding requirements on components: they must perform with absolute reliability under extreme temperatures, immense pressures, and corrosive environments, all while adhering to strict weight limitations. It is these very demands that make brass CNC turned parts a leading choice for critical applications.

Core Material Advantages for Demanding Environments

Brass alloys, particularly leaded brass like C36000 or other specialty brasses, possess an innate set of superior properties. According to the ASM international materials database, a recognized authority in materials science, brass offers a favorable combination of strength, excellent wear resistance, and outstanding corrosion resistance. This allows components to withstand exposure to fuels, lubricants, and various chemicals, ensuring long-term stability in aircraft hydraulic systems, fuel management units, and avionics.

: Meeting Complex Designs with Precision Machining

Aerospace components often feature intricate geometries and are sometimes needed in low volumes, a scenario perfectly suited for custom manufacturing solutions. CNC turning technology seamlessly interprets digital 3D models to produce brass parts with complex threads, precise boreholes, and tight tolerances. This flexibility ensures design intent is perfectly realized while supporting rapid prototyping and small-batch production, thereby accelerating development cycles.

- Rigorous Industry Certification as a Guarantee

In a high-stakes industry like aerospace, supplier qualifications are paramount. The AS9100D standard, an aerospace-specific quality management system based on ISO 9001, serves as a global passport into the aviation supply chain. A manufacturer holding this certification demonstrates that its entire process—from material sourcing to final inspection—is governed by a traceable, auditable, and continuously improving high-reliability system.

- Application Case Validation

For instance, in the manufacturing of an aerospace sensor, a tiny brass CNC turned Part such as a precision connector or housing must maintain dimensional stability and conductivity to ensure accurate signal transmission. Specialist manufacturers achieve this through high-precision turning, guaranteeing performance amidst vibration and thermal fluctuation. Detailed insights into such applications can be found in a comprehensive guide to Brass CNC Turned Parts.

: How is Cost Optimization Achieved Through CNC Turning in Automotive Parts Trends?

Current automotive parts trends are defined by electrification, connectivity, and lightweighting. These trends demand higher precision, greater complexity, and improved material performance from components, pushing manufacturers to find more efficient cost-control pathways. CNC turning technology, in conjunction with brass turning services, plays a pivotal role in this endeavor.

Lightweighting initiatives require maximal material utilization. Brass, with its favorable properties, is commonly used for key automotive components like sensor housings, electrical connectors, and valve bodies. Traditional methods can result in high scrap rates. In contrast, CNC turning uses sophisticated programming to optimize tool paths, drastically reducing raw material waste and leading to direct savings on material costs, which is significant for non-ferrous metals like brass.

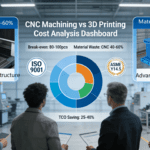

Deeper cost optimization stems from design refinement and production integration. Using advanced CAD/CAM software, engineers can perform topology optimization on brass components, creating lighter, more efficient structures without compromising strength. This design optimization, combined with the ability of CNC turning to complete multiple operations in a single setup, reduces the number of production steps, fixtures, and handling time. Industry practices show that such comprehensive optimization can lower total manufacturing costs by 15-20%.

Realizing these cost benefits depends on selecting a competent turned parts supplier. A superior supplier does not merely offer brass turning services; it acts as a manufacturing partner, providing early Design for Manufacturability (DFM) input to further reduce costs. Leveraging economies of scale and stable supply chain management, a reliable supplier can ensure competitive total cost of ownership without sacrificing quality.

: How Do Precision Component Manufacturers Ensure Quality and Compliance?

In specialized fields like aerospace and automotive, the selection of qualified brass precision turned components manufacturers is fundamental to project success. These manufacturers establish multi-layered systems for quality control and compliance to guarantee that every delivered part meets or exceeds specifications.

Building a Quality Foundation on International Standards

Authoritative international certifications are the primary benchmark of a manufacturer’s commitment. Beyond AS9100D for aerospace, IATF 16949 is the global quality management standard for the automotive industry, emphasizing defect prevention and waste reduction. For environmental management, ISO 14001 certification indicates a commitment to minimizing ecological impact. These systems require documented procedures, continuous monitoring, and regular audits, ensuring quality and compliance are systematic outputs, not accidental occurrences.

Integrating Advanced Manufacturing and Inspection Technologies

The core competency of a modern manufacturer of turned parts lies in the deep integration of advanced machining and precision metrology. High-precision, multi-axis CNC turning centers are the foundation for achieving complex geometries and micron-level tolerances. To verify these results, manufacturers must invest in coordinate measuring machines (CMMs), optical comparators, profilometers, and even industrial CT scanners. A rigorous process of first-article inspection, in-process checks, and final inspection creates a closed-loop quality data system, ensuring all brass precision turned components conform to design specifications.

- Full-Process Traceability Management

From the moment a brass bar stock is received, it is assigned a unique identification code that follows it through turning, cleaning, inspection, and packaging. This traceability allows for rapid root-cause analysis and corrective action in case of any quality concern, effectively isolating potential non-conforming products.

- A Culture of Continuous Improvement

Top-tier manufacturers view quality as a journey of continuous improvement. They employ Statistical Process Control (SPC) to monitor production in real-time, analyzing data to predict and prevent deviations. Regular reviews of quality performance, customer feedback, and new technologies drive ongoing process optimization. (To explore how a professional manufacturer implements its quality controls, one can review its detailed CNC turning services.

Expert Teams and Customer Collaboration

Ultimately, all systems and technologies are executed by people. Experienced engineers, programmers, and operators are the ultimate guarantors of quality. Furthermore, superior manufacturers prioritize early and continuous communication with clients, accurately translating technical requirements into internal production and inspection instructions. This collaboration is the final bridge to achieving a “zero-defect” goal.

What Are the Future Trends in Custom Manufacturing Solutions?

The future of custom manufacturing solutions is defined by smarter CNC industry trends, integrating AI and IoT into CNC turning. AI algorithms analyze machining data to optimize parameters in real-time, predict maintenance, and boost efficiency. IoT creates a “digital twin” of the factory, enabling real-time monitoring and agile scheduling.

Customization will evolve from manufacturing to print to designing for need. Clients may submit functional requirements, and AI-powered systems could generate optimized designs and machining code automatically, enabling highly personalized production with mass-production efficiency.

Materials likebrass remain vital, with a stronger focus on sustainability. Through precision CNC turning and hybrid manufacturing, material utilization will be maximized. The use of recycled brass and optimized energy consumption will ensure that precision brass manufacturing supports both performance and sustainable goals.

Conclusion

CNC turning technology provides a robust solution for overcoming manufacturing challenges in cost, precision, and supply chain volatility. It delivers significant gains in efficiency and quality, offering high-performance solutions for sectors like aerospace and automotive. Businesses seeking to enhance competitiveness should partner with an experienced provider.

For comprehensive support from design to machining, manufacturers such as JS Precision are a reliable choice for a more efficient manufacturing future.

Author Biography

This article was composed by a precision manufacturing specialist with a decade of industry experience. The author focuses on the research, application, and promotion of CNC machining technologies, dedicated to delivering the most advanced manufacturing concepts and practical solutions to the industry.

:FAQs

Q1: What are Brass CNC Turned Parts?

A1: Brass CNC turned Parts are brass rotational components machined using computer numerical control technology. They are characterized by high precision and excellent corrosion resistance, making them suitable for precision parts in aerospace and automotive applications, ensuring long-term stability.

Q2: How does CNC Turning help reduce manufacturing costs?

A2: By automating the machining process, it minimizes human error and material waste. Optimized designs can increase efficiency by 20%, leading to significant cost savings, especially in large-volume production.

Q3: What certifications should be considered when selecting a precision parts supplier?

A3: Priority should be given to certifications like ISO 9001 and AS9100D. These standards ensure a robust quality system and industry-specific compliance, mitigating supply chain risks.

Q4: What are the applications of brass parts in the automotive industry?

A4: They are primarily used in core components such as sensors and valves. Their electrical conductivity and wear resistance enhance automotive performance, while lightweight designs contribute to reduced energy consumption.

Q5: What is the typical delivery cycle for custom manufacturing solutions?

A5: Depending on complexity, it generally takes 1-3 weeks. Professional suppliers utilize digital workflows to accelerate time-to-production, ensuring timely delivery without compromising quality.