In the aviation industry, precision, reliability and safety are non-negotiable. Every component from structural metals to fasteners, tubing, fittings and hardware must meet strict standards to ensure aircraft can operate safely under demanding conditions. Working with a trusted distributor of aircraft materials and supplies is essential for maintaining consistency, performance and compliance across all aviation projects.

Whether you’re involved in aircraft maintenance, repair, manufacturing or specialised engineering, access to high-quality materials is crucial.

The Role of a Trusted Aircraft Materials Distributor

A professional distributor does more than supply metal and parts — they support the entire aviation supply chain by providing:

- Certified and traceable materials

- Reliable stock availability

- Expert guidance on material selection

- Fast delivery for urgent maintenance and repair needs

- Consistent quality across every order

This ensures aircraft operators, MROs, engineers and fabricators can work efficiently and safely.

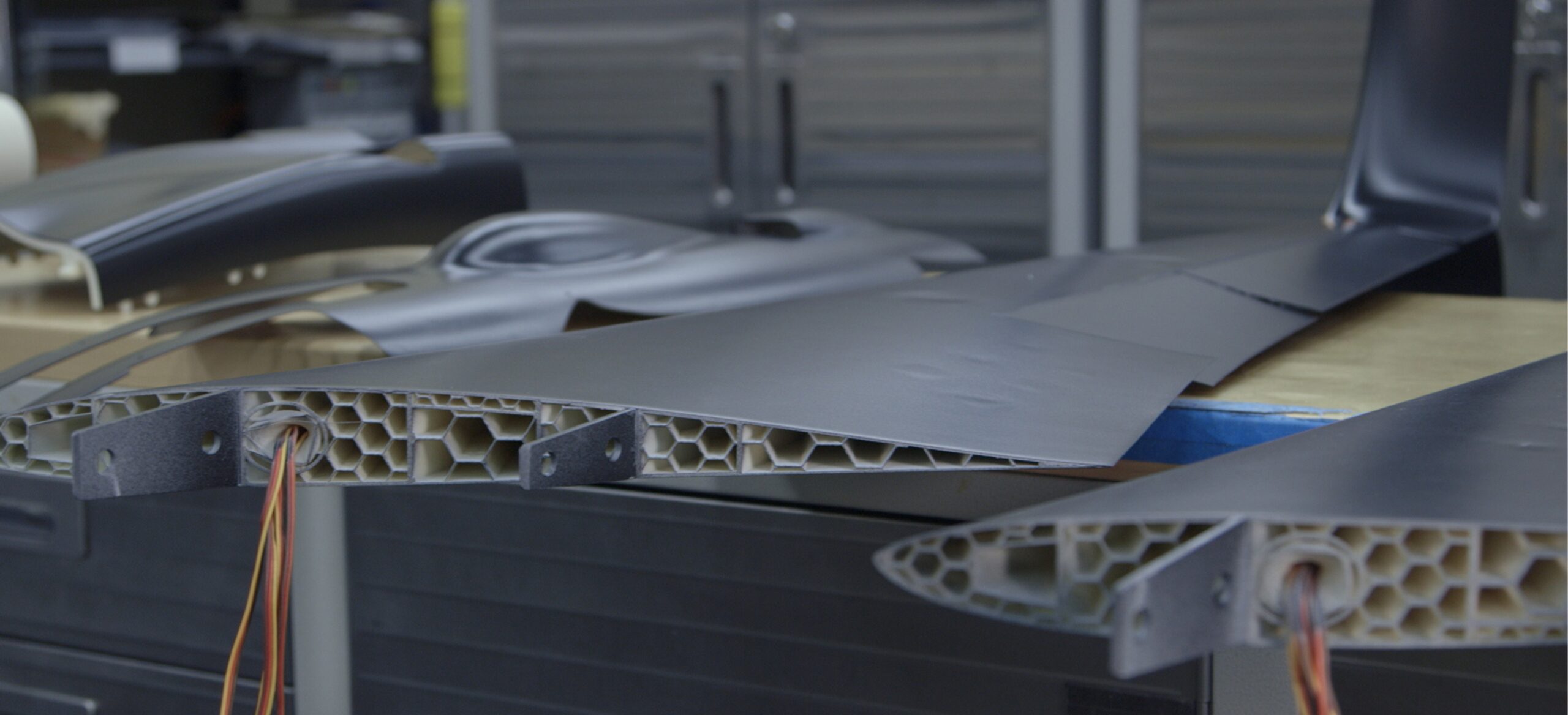

What Types of Materials Are Commonly Used in Aviation?

High-performance aerospace materials are chosen for their strength, durability, weight efficiency and resistance to extreme conditions. Common materials include:

- Aluminium sheets, plates and extrusions

- Stainless steel and carbon steel tubing

- Titanium materials

- Steel and alloy fittings

- Aviation-grade fasteners and hardware

- Specialised metals for structural and mechanical applications

Each material serves a specific purpose and must meet aviation standards for performance and safety.

Why Material Certification & Traceability Are Critical

Aviation regulators require that all materials used in aircraft manufacturing and repairs have full traceability. This includes:

- Batch numbers

- Manufacturing documentation

- Compliance certificates

- Inspection records

- Material specifications

Using uncertified materials can lead to compliance failure, compromised aircraft safety and costly rework. A reputable distributor of aircraft materials and supplies ensures full documentation accompanies every component.

Key Benefits of Working with a Specialist Aircraft Materials Distributor

✔ Consistent Quality Assurance

Aircraft components operate under immense stress. High-quality, certified materials ensure reliability and long-term performance.

✔ Reduced Downtime

With dependable stock availability and quick dispatch, maintenance and repair operations can continue without delay.

✔ Expert Industry Knowledge

Specialist suppliers understand aviation-grade metals and can recommend the best materials for specific applications.

✔ Better Project Efficiency

Having a single, trusted supplier streamlines procurement and reduces administrative workload.

✔ Compliance with Aviation Standards

Meeting strict industry regulations is easier when sourcing from accredited distributors.

Who Relies on Aircraft Materials Distributors?

- Aircraft maintenance organisations (MROs)

- Engineering and fabrication workshops

- Aviation manufacturing facilities

- Defence and aerospace contractors

- Light aircraft operators

- Commercial airline service teams

- Motorsport and precision engineering industries needing aerospace-grade metals

Their projects all demand consistent, high-quality materials with proven reliability.

Final Thoughts

Choosing the right distributor of aircraft materials and supplies ensures your aviation projects meet the highest standards of safety, durability and performance. From certified metals to essential fittings and components, working with a trusted supplier helps maintain smooth operations, reliable aircraft performance and complete compliance with industry requirements.