Introduction

Fire safety today extends far beyond basic regulatory compliance. Industries are expected to protect human life, safeguard valuable assets, and minimize environmental impact simultaneously. As materials become more advanced and product designs increasingly compact, the demand for reliable and responsible fire protection solutions has intensified.

For decades, flame retardant chemicals have played a critical role in reducing ignition risks and slowing flame spread. However, growing awareness of health and environmental concerns has accelerated the shift toward safer alternatives, particularly halogen free flame retardant systems. These next-generation technologies are redefining fire safety standards across multiple industries worldwide.

Understanding Flame Retardant Chemicals

What Are Flame Retardant Chemicals?

Flame retardant chemicals are additives or reactive compounds incorporated into materials to delay ignition, reduce heat release, or slow the spread of fire. They are widely used in both consumer and industrial products, including:

- Electrical cables and wiring systems

- Electronic enclosures and housings

- Furniture and upholstery

- Construction insulation materials

- Automotive and transportation components

Their primary function is to increase the time available for evacuation and emergency response. Even a brief delay in combustion can significantly reduce property damage and save lives.

Why They Are Essential in Modern Industries

Modern manufacturing relies heavily on polymers, lightweight composites, and compact electronic systems—materials that can pose elevated fire risks. Flame retardants help manufacturers meet fire performance standards such as UL 94, ASTM testing protocols, and IEC guidelines, while ensuring product durability and consumer safety.

Limitations of Traditional Flame Retardants

Health and Toxicity Concerns

Many conventional flame retardants, particularly halogenated compounds containing bromine or chlorine, are highly effective at suppressing flames. However, during combustion, some may release dense smoke and corrosive gases that increase health risks for occupants and emergency responders.

Regulatory agencies, including the European Chemicals Agency (ECHA), have evaluated several halogenated substances due to concerns about long-term exposure, environmental persistence, and potential bioaccumulation.

Environmental Persistence

Certain halogenated compounds can remain in soil and water systems for extended periods. As global environmental regulations continue to tighten, manufacturers face increasing pressure to adopt safer and more sustainable fire protection solutions.

What Is Halogen Free Flame Retardant?

A Safer Alternative Explained

A halogen free flame retardant system does not contain chlorine or bromine. Instead, it relies on alternative materials such as:

- Phosphorus-based compounds

- Nitrogen-based systems

- Aluminum hydroxide

- Magnesium hydroxide

These solutions are engineered to deliver effective fire resistance while minimizing toxic smoke and corrosive by-products during combustion.

Why Halogen-Free Solutions Matter

In real fire scenarios, smoke inhalation—not flames—is often the leading cause of fatalities. Independent fire testing conducted under internationally recognized standards indicates that halogen-free systems can significantly reduce smoke density compared to many traditional halogenated materials. Lower smoke levels improve visibility during evacuation and reduce toxic exposure.

How Halogen Free Flame Retardants Work

Condensed Phase Protection

Many halogen-free formulations form a protective char layer when exposed to heat. This carbonized barrier insulates the underlying material, restricts oxygen access, and slows heat transfer, helping suppress further combustion.

Gas Phase Action

Some systems release non-toxic gases that dilute oxygen concentration around the flame. This interrupts the combustion process without generating harmful acid gases or corrosive residues.

Key Benefits for Modern Industries

Enhanced Human Safety

Halogen-free flame retardants offer multiple safety advantages, including:

- Reduced smoke density

- Lower toxic emissions

- Minimal corrosive gas formation

These factors improve occupant safety and reduce risks for firefighters and emergency responders.

Environmental Responsibility

Halogen-free materials are generally less persistent in ecosystems and align more closely with sustainability initiatives. Many manufacturers adopt them to support ESG commitments, green building certifications, and long-term environmental objectives.

Regulatory Compliance

Halogen-free flame retardants help companies comply with major global regulations, including:

- RoHS (Restriction of Hazardous Substances)

- REACH regulations

- International environmental and sustainability standards

Selecting compliant materials proactively reduces regulatory risks and market access barriers.

Industry Applications

Electronics and Electrical Systems

Halogen-free flame retardants are widely used in circuit boards, cable insulation, connectors, and enclosures, helping manufacturers meet strict fire safety and environmental performance requirements.

Construction and Infrastructure

In construction, these solutions are applied in insulation, wall systems, coatings, and roofing materials. Reduced smoke emission is particularly critical in enclosed spaces such as offices, residential buildings, and public facilities.

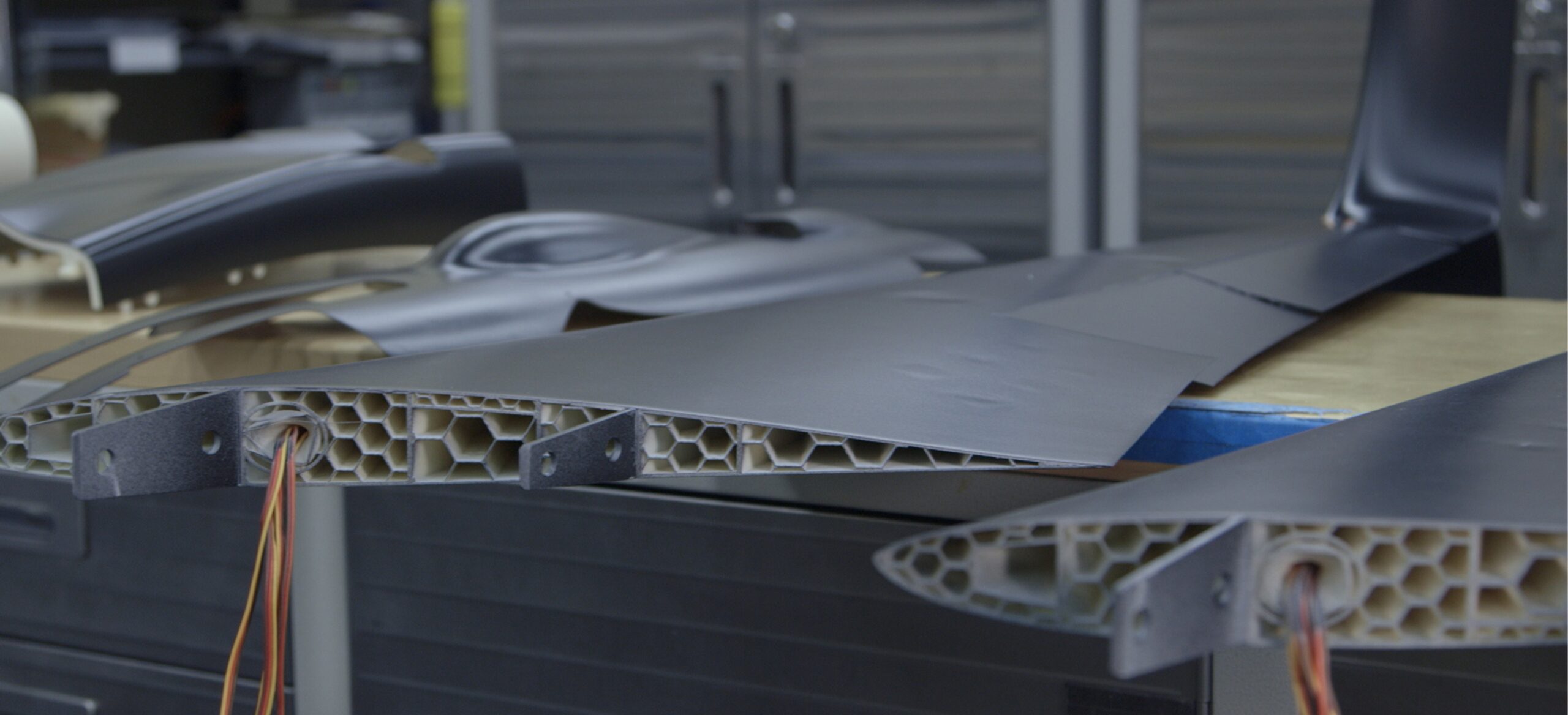

Automotive and Transportation

From interior panels to wiring harnesses, halogen-free flame retardants enhance passenger safety and limit toxic exposure in confined environments, including electric and hybrid vehicles.

Case Insight: Performance in Fire Testing

Fire safety assessments conducted under internationally recognized standards such as UL and IEC testing protocols show that halogen-free materials can deliver competitive flame resistance while producing substantially lower smoke output than many conventional halogenated systems. This balance of safety and performance is a major factor driving their growing adoption in high-risk industries.

Choosing the Right Flame Retardant Solution

When selecting between traditional and halogen-free flame retardant chemicals, decision-makers should consider:

- Required fire performance ratings

- Smoke and toxicity limits

- Environmental impact

- Regulatory compliance requirements

- Long-term brand reputation and liability

For many forward-looking organizations, halogen-free solutions represent a future-ready investment in safety, compliance, and sustainability.

Conclusion

Fire protection strategies are evolving in response to stricter regulations, heightened environmental awareness, and rising expectations for corporate responsibility. While traditional flame retardant chemicals continue to play important roles, the transition toward halogen free flame retardant technologies reflects a broader shift toward safer and more sustainable innovation.

By adopting advanced, low-toxicity solutions, industries can strengthen fire safety performance, reduce environmental harm, and build long-term trust with regulators and consumers alike. In today’s safety-driven landscape, halogen-free fire protection is no longer just an alternative—they are rapidly becoming an industry standard.

flame retardant chemicals

Frequently Asked Questions (FAQs)

1. What is the main difference between halogenated and halogen-free flame retardants?

Halogenated flame retardants contain chlorine or bromine and may produce toxic smoke during fires. Halogen-free alternatives avoid these elements and generate significantly lower toxic and corrosive emissions.

2. Are halogen-free flame retardants as effective as traditional options?

Yes. When properly formulated, halogen-free flame retardants can meet international fire safety standards while offering improved smoke and toxicity performance.

3. Do halogen-free flame retardants cost more?

Initial costs may be slightly higher, but long-term benefits such as regulatory compliance, reduced liability, and improved safety often outweigh the upfront investment.

4. Which industries benefit most from halogen-free flame retardants?

Electronics, construction, automotive, transportation, and electrical industries benefit significantly due to strict fire safety and environmental regulations.

5. Are halogen-free flame retardants environmentally responsible?

They are generally considered more environmentally responsible than halogenated alternatives because they are less persistent, produce fewer toxic by-products, and align with sustainability goals.