Your electrical panel is the heart of your home’s power system. Every circuit runs through it, every safety device depends on it, and every electrical failure ultimately traces back to it. But most homeowners never look inside their panel until something goes wrong.

By that time, the problem might be serious. Panels don’t fail suddenly like light bulbs. They deteriorate gradually, showing warning signs most people don’t recognize until an electrician points them out.

When we evaluate homes for electrical panel replacement Fort Collins, the clients often don’t realize how many red flags their panels are showing.

Understanding what electricians look for helps you know when replacement is necessary versus optional.

Age of the Panel

The first thing electricians check is how old your panel is. Age alone doesn’t always mean replacement, but it’s a critical factor.

Panels Over 25 Years Old

Most electrical panels have a lifespan of 25-40 years. Once your panel hits 25 years, components start degrading even if everything appears functional. Breakers wear out, bus bars oxidize, connections loosen, and internal components lose reliability.

Panels from the 1970s and 80s served homes with completely different electrical demands. They weren’t designed for modern loads from computers, appliances, HVAC systems, and electric vehicles.

Technology Has Changed

Safety technology has advanced significantly. Modern panels include AFCI and GFCI protection, better materials, improved breaker designs, and enhanced safety electrical features that older panels simply don’t have.

Even if your old panel still works, it lacks the protections that prevent fires and electrocution in ways older technology couldn’t.

Specific Problematic Brands

Certain panel brands have known defects so serious that replacement is recommended regardless of apparent condition.

Federal Pacific Electric Panels

FPE panels were installed in millions of homes between the 1950s and 1980s. Testing has shown their breakers fail to trip during overcurrent conditions up to 60% of the time.

When breakers don’t trip, electrical faults continue unchecked. Wires overheat, insulation melts, and fires start. These panels have been linked to thousands of fires and electrical failures.

If you have an FPE panel, replacement isn’t optional. It’s a safety necessity.

Zinsco Panels

Zinsco panels have similar failure rates to FPE. The breakers fuse to the bus bars, preventing them from tripping even during dangerous overloads. Aluminum bus bars in these panels corrode and overheat.

Like FPE panels, Zinsco’s presence alone justifies replacement regardless of current function.

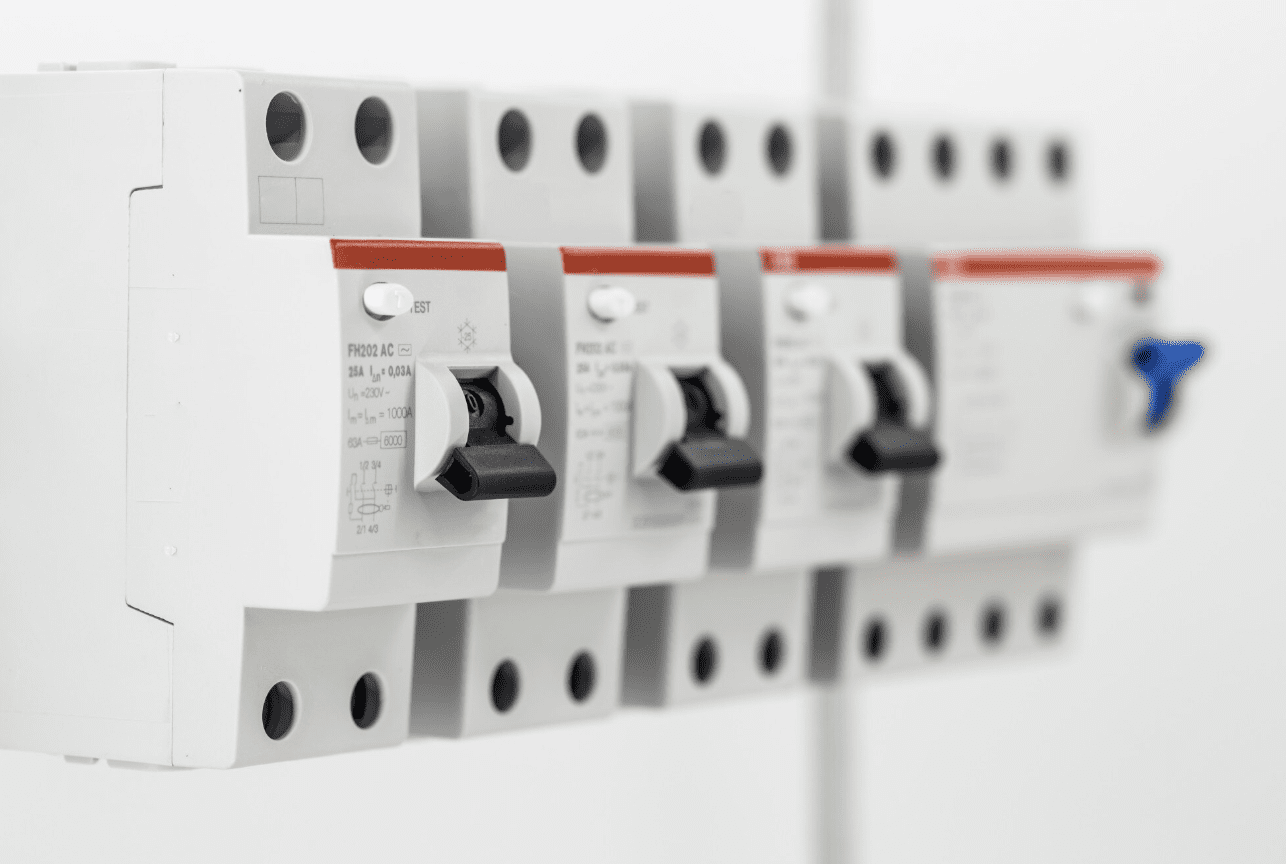

Physical Signs of Deterioration

Electricians open your panel and look for specific physical warning signs that indicate replacement is needed.

Rust and Corrosion

Any rust inside your panel is a red flag. It indicates moisture infiltration, which creates multiple problems. Corroded connections increase resistance and generate heat. Rust on bus bars or breakers compromises electrical contact.

Even surface rust suggests ongoing moisture issues that will continue degrading components.

Burn Marks or Discoloration

Dark discoloration or burn marks around breakers or connections indicate overheating. This means connections are loose or components are failing. The damage you see on the surface often indicates worse problems inside components.

Heat damage compromises the integrity of plastic housings, wire insulation, and breaker internals. Once this degradation starts, it accelerates over time.

Melted or Damaged Components

Melted plastic, burned insulation, or visibly damaged breakers mean serious problems already occurred. The panel experienced enough heat to physically damage components. That level of heat doesn’t happen in properly functioning panels.

This damage indicates either massive overloads, serious faults, or component failures. All justify panel replacement.

Capacity and Circuit Issues

Your panel needs enough capacity for current and future electrical needs. Electricians evaluate whether your panel can handle your home’s demands.

Insufficient Amperage

Older homes often have 60-amp or 100-amp service. Modern homes typically need 200 amps minimum. If you’re constantly managing loads to avoid tripping breakers, your service is undersized.

Adding major appliances, electric vehicle chargers, or home additions requires capacity that most older panels don’t have. Upgrading the service means replacing the panel.

No Available Spaces

When every breaker position is full, and you need to add circuits, you have a problem. Some people use tandem breakers to squeeze extra circuits into full panels, but this often overloads the panel beyond its rating.

Full panels with no expansion room limit what you can do with your home. Replacement provides capacity for current needs plus future additions.

Double-Tapped Breakers

Double-tapping means two circuits connect to one breaker. This violates code (except for breakers specifically rated for it) and creates safety issues. The breaker can’t properly protect both circuits, connections are often poor, and overcurrent protection is compromised.

Finding multiple double-tapped breakers indicates capacity problems and improper modifications. Both suggest replacement is warranted.

Safety Feature Deficiencies

Modern electrical code requires safety features that many older panels don’t have. While you’re not always required to upgrade, the lack of these features increases risks.

No AFCI or GFCI Protection

Arc Fault Circuit Interrupters prevent fires by detecting dangerous arcing. GFCI protection prevents electrocution in wet locations. Both are code requirements for new installations.

Older panels can’t accommodate these protections without significant modifications. Panel replacement allows adding modern safety features throughout your home.

Inadequate Grounding

Proper grounding protects against shocks and electrical faults. Older panels sometimes lack adequate grounding or use outdated grounding methods that don’t meet current safety standards.

Upgrading grounding often requires panel work extensive enough that replacement makes more sense than patching together old systems.

Performance Problems

How your electrical system performs reveals panel condition even when nothing looks obviously wrong.

Frequent Breaker Trips

If breakers trip regularly without obvious overloads, they might be wearing out. Breakers have mechanical parts that degrade over time. Old breakers become oversensitive or fail to trip when they should.

Replacing individual breakers in old panels doesn’t always help because the problem might be panel-wide component degradation, not just individual breaker failure.

Flickering Lights

Lights that dim or flicker when appliances start suggest connection problems or insufficient capacity. While this isn’t always a panel issue, panels with loose bus bar connections or corroded components contribute to voltage fluctuations.

Warm Panel or Burning Smell

Panels should never feel warm to the touch or produce burning smells. Either symptom means serious overheating from loose connections, overloaded circuits, or failing components.

This is an emergency situation requiring immediate professional evaluation. Continued use risks fire.

Home Modifications That Trigger Replacement

Certain changes to your home create electrical demands your existing panel can’t handle safely.

Major Renovations

Adding square footage, finishing basements, or creating home offices requires new circuits. If your panel lacks capacity or available spaces, renovation work triggers panel replacement.

EV Charger Installation

Electric vehicle chargers draw significant power. Level 2 chargers typically require dedicated 40-50 amp circuits. Many older panels can’t support this added load without exceeding their total capacity.

Solar Panel Integration

Solar installations require specific electrical configurations and often need service upgrades. Integrating solar typically means replacing or significantly modifying your existing panel.

Insurance and Resale Considerations

Beyond safety and functionality, panel condition affects insurance and property value.

Insurance Requirements

Some insurance companies refuse coverage or charge higher premiums for homes with FPE, Zinsco, or other problematic panels. They might require replacement as a condition of coverage.

Getting quotes before replacing panels sometimes reveals that replacement pays for itself through reduced insurance costs over time.

Home Sale Complications

Outdated or problematic panels create issues during home sales. Inspectors flag them, buyers demand corrections, and deals sometimes fall through over electrical concerns.

Replacing panels before listing eliminates a major negotiating point and can actually increase your home’s value by removing a significant defect.

The Inspection Process

When electricians evaluate whether your panel needs replacement, they follow a systematic process.

They check manufacturer and model against known defective brands, verify panel age and service capacity, inspect for physical damage or deterioration, test breaker operation and connections, evaluate if capacity meets current loads, look for code violations or improper modifications, and assess whether modern safety features are present.

This comprehensive evaluation reveals whether your panel is safe, adequate, and likely to remain reliable or whether replacement is necessary.

Cost vs. Risk Analysis

Panel replacement typically costs $1,500-$4,000, depending on service size and complexity. That seems expensive until you consider the alternatives.

Electrical fires cause billions in property damage annually. Many trace back to panel failures that showed warning signs for years. The cost of rebuilding after a fire, or worse, losing family members, makes panel replacement look like cheap insurance.

Beyond catastrophic risks, inadequate panels limit what you can do with your home and create daily frustrations from capacity limitations.

When Replacement Is Necessary

Based on the factors above, electricians recommend immediate replacement when you have FPE, Zinsco, or other defective brands, visible damage like burn marks or melting, frequent overheating or burning smells, severe rust or corrosion, insufficient capacity for current needs, or panels over 40 years old showing any deterioration.

These conditions create unacceptable safety risks that outweigh any cost concerns.

Making the Decision

If your panel is aging but not showing serious problems, you face a judgment call. Electricians can help weigh factors like your home’s age and condition, your future electrical plans, current panel performance, and safety feature deficiencies.

Sometimes waiting makes sense if budgets are tight and risks are low. Other times, addressing problems proactively prevents emergencies and provides peace of mind.

Professional evaluation gives you the information to make informed decisions about timing and necessity.

Your electrical panel deserves attention proportional to its importance. It’s literally the safety hub for your entire electrical system. When electricians recommend replacement, they’re basing that recommendation on real risks and observable conditions that compromise safety.

Don’t wait for catastrophic failure to address panel problems. The warning signs are there if you know what to look for.