n today’s electronics landscape, choosing the right PCBA manufacturer is more than just selecting a partner — it’s about ensuring compliance, quality, and sustainability across your products’ lifecycle. As global regulations like the RoHS (Restriction of Hazardous Substances) directive continue to expand, lead-free PCB assembly has shifted from a niche requirement to an industry standard for companies that want to compete internationally and responsibly. For brands seeking reliable and compliant electronics, working with a manufacturer experienced in lead-free processes — such as PCBasic — can make all the difference in quality, environmental compliance, and time-to-market.

What Is Lead-Free PCB Assembly?

Lead-free PCB assembly refers to the process of assembling printed circuit boards using solder and materials that contain zero or only trace amounts of lead — typically less than 0.1% to meet RoHS requirements. Traditional leaded solder (such as tin-lead alloys) once dominated electronics manufacturing due to its low melting point and ease of use, but mounting environmental and health concerns have driven the industry toward lead-free alternatives composed of alloys like Sn-Ag-Cu (SAC305) and other tin-based formulations.

Why Lead-Free Matters: Compliance and Beyond

Over the past decade, electronic manufacturers have embraced lead-free PCB assembly not only to comply with environmental laws but also to boost product appeal and market access:

- Global Regulatory Compliance — Lead-free assemblies are required for products sold in the EU, UK, and many other major markets under RoHS and similar directives.

- Health and Safety Benefits — Eliminating lead from PCBA reduces occupational exposure risks during manufacturing and lowers toxicity in end-of-life recycling.

- Market and Brand Value — Eco-friendly products appeal to environmentally conscious consumers and improve brand reputation.

Lead-free solder requires slightly higher reflow temperatures (commonly around 240°C–270°C) compared to leaded solder, which demands thoughtful thermal profiling and capable PCB materials to ensure reliability.

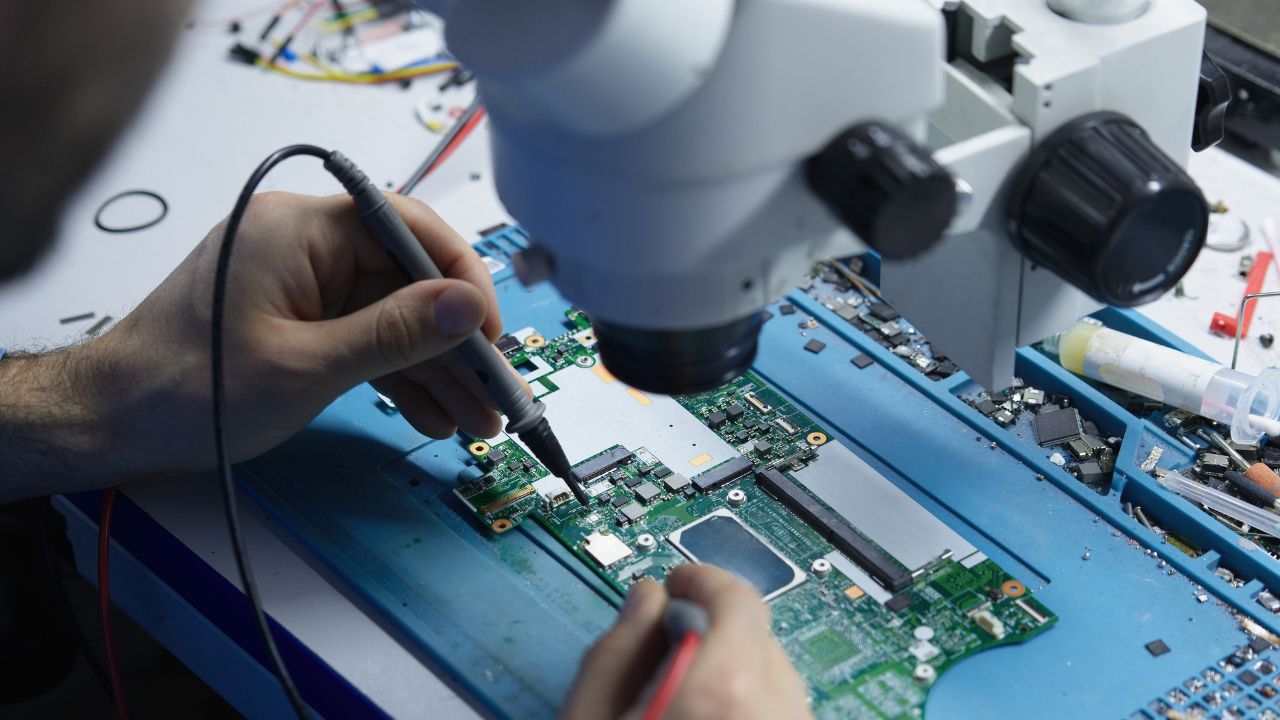

Core Steps in Lead-Free PCB Assembly

A successful lead-free process involves meticulous controls at each stage:

Material Selection

- Only RoHS-certified substrates, solder pastes, and components are used. This ensures the entire build is free of restricted substances.

Solder Paste Printing & Placement

- Lead-free solder paste, typically SAC alloys, is printed and parts are accurately placed using automated SMT machines.

Reflow Soldering

- Using optimized lead-free profiles, boards pass through a reflow oven where the solder bonds components to the PCB.

Inspection & Testing

- Advanced inspection methods (AOI, X-ray, flying probe tests) ensure joints meet quality and reliability standards.

Final QA & Packaging

- Boards undergo functional testing before packaging and shipment — all within a fully controlled lead-free environment.

Why Choose PCBasic for Lead-Free PCB Assembly?

As a globally recognized PCB and PCBA manufacturer with over 15 years of experience, PCBasic offers comprehensive lead-free PCB assembly services designed to help clients meet regulatory, reliability, and performance goals.

- 100% Lead-Free Production Lines: Dedicated SMT and through-hole assembly lines are strictly controlled to prevent contamination from leaded processes.

- Strict Quality Assurance: All assemblies undergo rigorous inspections including AOI and X-ray to ensure defect-free products that meet IPC standards.

- Global Compliance: Every build aligns with RoHS and related environmental requirements so your products can be sold worldwide.

- Wide Industry Coverage: From consumer electronics to automotive and medical applications, PCBasic’s lead-free PCBA services are versatile and robust.

Summary: Building Sustainable Electronics

Lead-free PCB assembly is no longer optional for companies aiming to succeed in regulated global markets. Its benefits span compliance, sustainability, and product performance. Partnering with an experienced PCBA manufacturer like PCBasic ensures your designs are produced with the highest quality standards while meeting stringent lead-free requirements — helping your products perform reliably and responsibly in the world’s most demanding applications.