Modern infrastructure relies heavily on complex electrical and data systems that operate quietly behind the scenes. From commercial buildings to industrial facilities, cables form the backbone of power distribution, communication, and automation. Understanding how cables are manufactured and why quality matters helps explain their critical role in keeping systems safe and reliable.

As demand for advanced electrical systems grows, businesses increasingly depend on specialized providers offering a cable manufacturing service that can meet technical standards, environmental requirements, and performance expectations without compromising safety or durability.

Understanding Cable Manufacturing at a Fundamental Level

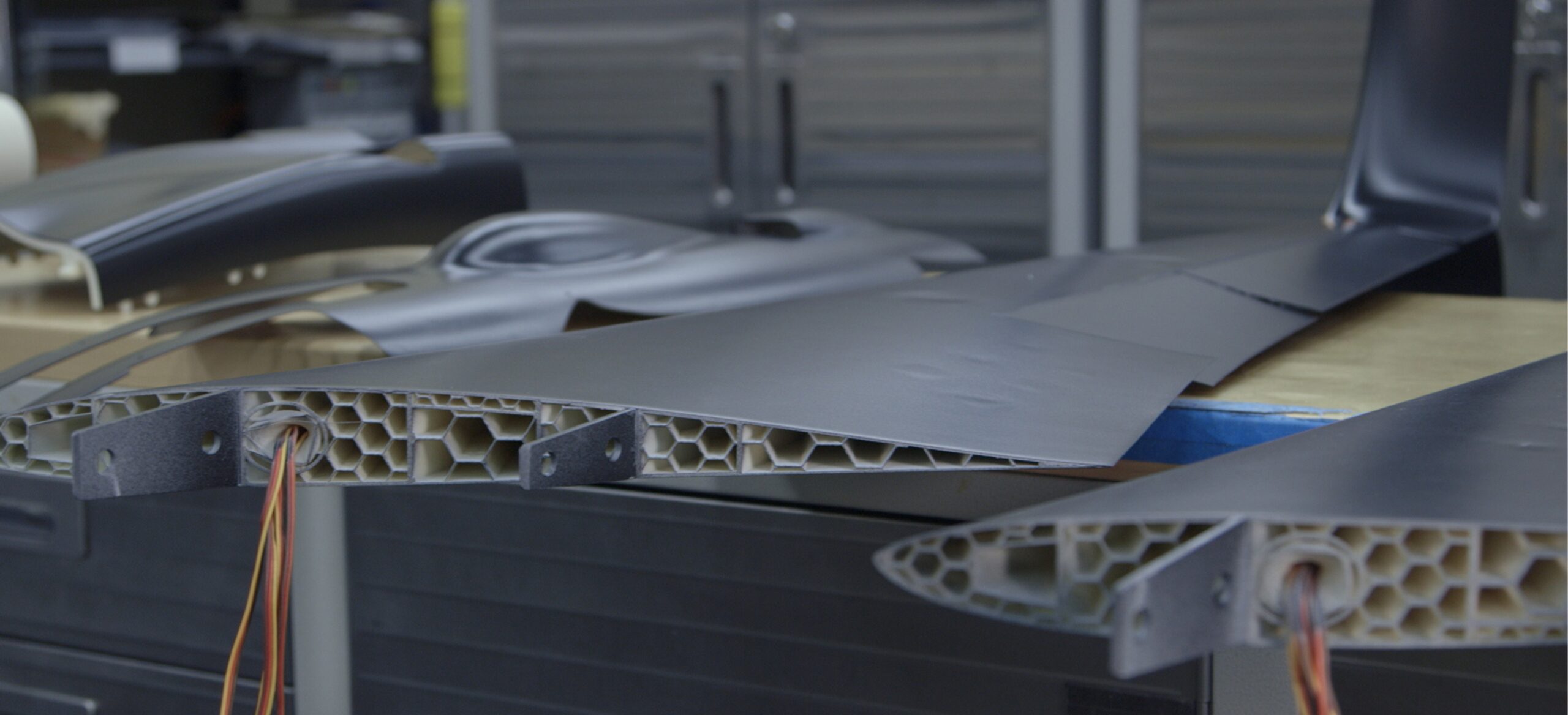

Cable manufacturing involves more than assembling conductive materials inside insulation. It is a controlled process that combines engineering design, material science, and precision manufacturing. Each cable is designed to meet specific electrical loads, temperature ranges, and mechanical stresses.

The process typically includes conductor preparation, insulation extrusion, shielding, jacketing, and testing. Each stage must follow strict tolerances to ensure the cable performs as intended throughout its service life. Even small variations in materials or construction can affect conductivity, resistance, or heat dissipation.

Why Material Selection Matters in Cable Production

The performance of a cable depends heavily on the materials used. Conductors are commonly made from copper or aluminum, selected based on conductivity requirements, flexibility, and cost considerations. Insulation materials are chosen to resist heat, moisture, chemicals, or abrasion depending on where the cable will be installed.

For example, cables used in industrial environments often require insulation that can withstand high temperatures and mechanical stress. In contrast, data cables prioritize signal integrity and interference reduction. Material selection directly influences durability, safety, and long term reliability.

Custom Cable Solutions Versus Standard Products

Standard off-the-shelf cables are suitable for many applications, but they do not always meet the needs of complex or specialized systems. Custom cable manufacturing allows for adjustments in length, conductor size, insulation type, and protective layers.

This flexibility is especially valuable in industries such as construction, mining, automation, and renewable energy. Custom solutions reduce installation issues, minimize energy loss, and help systems operate efficiently. They also lower the risk of premature failure caused by mismatched specifications.

Quality Control and Compliance in Cable Manufacturing

Quality control is a core element of professional cable manufacturing. Reputable manufacturers test cables for electrical performance, insulation resistance, tensile strength, and environmental durability. These tests help identify defects before cables are installed in critical systems.

Compliance with local and international standards is equally important. Regulatory requirements exist to protect equipment, property, and people from electrical hazards. Proper testing and certification ensure that cables meet safety benchmarks and can be used confidently in demanding environments.

Applications Across Industries and Sectors

Cable manufacturing services support a wide range of industries. In commercial buildings, cables distribute power and enable communication systems. In industrial settings, they support machinery, automation, and control systems. Infrastructure projects depend on reliable cabling for transportation networks, utilities, and public facilities.

As technology advances, demand for specialized cables continues to increase. Renewable energy systems, data centers, and smart infrastructure all require cables designed for specific performance conditions. Manufacturing expertise plays a key role in meeting these evolving needs.

The Importance of Long Term Reliability

Cables are often installed in locations that are difficult or costly to access once a project is complete. Because of this, reliability over time is critical. Poorly manufactured cables can lead to downtime, safety risks, and expensive repairs.

High quality manufacturing reduces these risks by ensuring consistent performance under real world conditions. Proper design, material selection, and testing help cables maintain functionality throughout their expected lifespan, even in challenging environments.