Introduction

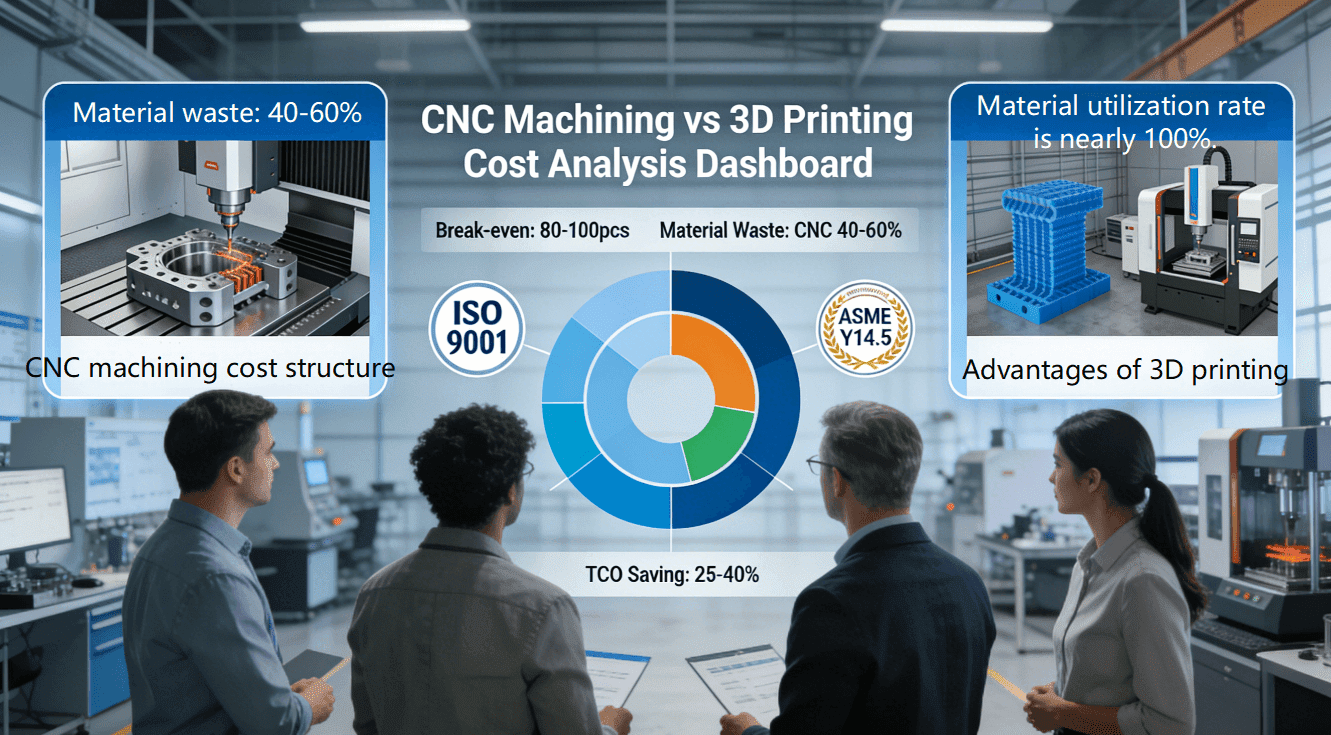

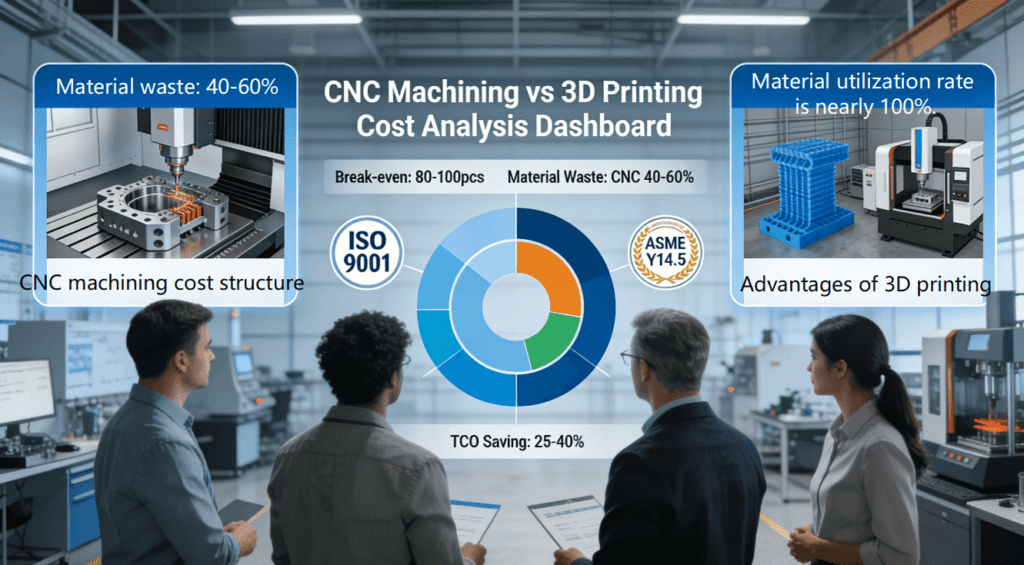

In today’s competitive manufacturing environment, many companies face critical decisions during prototype development and small-batch production: whether to choose CNC machining or 3D printing. Poor choices often lead to budget overruns, delivery delays, and compromised product performance. The root problem lies in traditional decision-making that relies too heavily on per-part cost or intuition, lacking a systematic analysis of Total Cost of Ownership (TCO) that considers key variables like production volume, geometric complexity, and delivery time.

This article provides a data-driven manufacturing cost analysis framework that quantifies the true cost drivers of both processes, helping businesses make scientific decisions. By referencing standards like ASME Y14.5 for precision control and ISO 9001 for process standardization, we demonstrate how to achieve cost control and efficiency improvements. The following sections will deconstruct the cost structures of both processes and provide a actionable decision-making framework.

What Are the Fundamental Cost Drivers in CNC Machining and 3D Printing?

Understanding the fundamental cost structures of both processes is essential for accurate comparison and selection. This section breaks down the key cost components that influence the total expenditure for each technology.

CNC Machining Cost Structure Analysis

CNC machining costs are primarily driven by three main factors: raw material blanks (40-60% of total cost), machine time and labor (25-35%), and tooling wear (10-15%). The “subtractive” nature of CNC machining results in material utilization rates typically between 40-60%, making material waste a significant cost variable. For high-volume production, the initial setup costs can be amortized, but for small batches, the per-part cost remains high due to substantial initial investments in programming and fixturing.

2. 3D Printing Cost Components Breakdown

3D printing costs differ substantially, with specialized materials accounting for 50-70% of total expenses, equipment amortization comprising 20-30%, and post-processing labor making up the remainder. The key advantage lies in near-100% material utilization, as the additive process only uses material where needed. However, the specialized materials often come at a premium, and equipment costs can be substantial for industrial-grade systems.

3. Comparative Analysis and Key Differentiators

A side-by-side comparison reveals that while 3D printing offers better material utilization, CNC machining provides superior surface finish and precision. The break-even point between the two processes depends heavily on production volume and part complexity. For simple geometries in medium to high volumes, CNC machining often becomes more economical due to faster cycle times, while 3D printing gains advantage for complex, low-volume parts where tooling costs would be prohibitive.

How Does Production Volume Directly Impact the Breakeven Point?

Production volume serves as a critical decision variable in process selection, directly influencing the economic viability of each manufacturing method. Understanding this relationship is crucial for cost optimization.

- Volume-Based Cost Dynamics: The breakeven analysis between CNC machining and 3D printing typically occurs around 80-100 pieces for simple geometric parts. This is because CNC machining involves high initial setup costs that become distributed across larger production runs, significantly reducing the per-part cost. In contrast, 3D printing costs remain relatively linear regardless of quantity, as there are minimal setup requirements but consistent material and machine time expenses per part.

- Economies of Scale in Manufacturing: High-volume production favors CNC machining due to economies of scale. Once the initial programming and setup are complete, each additional unit costs progressively less to produce. The marginal cost reduction becomes particularly significant after the first 50-100 units, making CNC machining the preferred choice for mass production scenarios where the same part is manufactured repeatedly.

- Strategic Implications for Different Volume Ranges: For prototype development and very low volumes (1-20 units), 3D printing generally offers cost advantages due to minimal setup requirements. For medium volumes (20-100 units), the decision requires careful analysis of part complexity and material requirements. For production volume optimization beyond 100 units, CNC machining typically becomes more economical, provided the parts don’t have extreme complexity that would require expensive multi-axis machining or special tooling.

When Does Part Complexity Change the Economic Calculus?

Part complexity dramatically alters the cost equation between CNC machining and 3D printing, often shifting the economic advantage from one process to the other based on geometric characteristics.

1. Complexity-Induced Cost Escalation in CNC

As part complexity increases with features like internal channels, lattice structures, or organic shapes, CNC machining costs rise significantly due to requirements for multi-axis machines, special fixtures, and longer machining times. Complex geometries often necessitate 5-axis machining capabilities, substantially increasing hourly machine rates and programming complexity. The need for multiple setups and specialized tooling further drives up costs for intricate designs.

2. Complexity-Neutral Cost Structure of 3D Printing

3D printing costs remain largely unaffected by geometric complexity since the additive process builds parts layer by layer regardless of shape intricacies. This makes additive manufacturing particularly advantageous for highly complex components where CNC machining would require multiple operations, special fixtures, and result in significant material waste. The economic advantage of 3D printing grows substantially as complexity increases.

3. Revised Breakeven Points for Complex Parts

For complex components with internal structures or organic geometries, the economic breakeven point can shift to 200-300 units or higher. In some cases of extreme complexity, 3D printing may remain economically superior regardless of volume. This makes 3D printing services particularly valuable for applications requiring customization, lightweight structures, or integrated assemblies that would be impossible or prohibitively expensive to manufacture using subtractive methods.

How Can a Hybrid Manufacturing Strategy Optimize Both Cost and Performance?

A hybrid approach that leverages the strengths of both manufacturing processes often delivers superior results than relying exclusively on either technology alone. This integrated strategy maximizes cost efficiency while meeting performance requirements.

1. Combining Additive and Subtractive Advantages

Hybrid manufacturing strategically employs 3D printing for creating complex near-net-shape components followed by CNC machining for precision finishing of critical features and interfaces. This approach marries the design freedom of additive manufacturing with the superior accuracy of subtractive processes. Research indicates that scientific analysis of CNC machining vs. 3D printing forms the foundation for implementing effective hybrid manufacturing strategies that can reduce total costs by 25-40% while enhancing product performance.

2. Implementation Framework for Hybrid Solutions

Successful implementation requires careful process selection based on part geometry, material requirements, and quality specifications. Typically, the additive process creates the basic shape with material and time efficiency, while the subtractive process achieves final dimensions and surface finish requirements. This approach is particularly valuable for parts requiring both complex internal features and high-precision mating surfaces.

3. Supply Chain Efficiency Gains

By optimizing business process selection and implementing hybrid manufacturing strategies, companies achieve significant supply chain efficiency improvements. The reduced lead times, lower tooling costs, and decreased material waste contribute to leaner operations. Additionally, the ability to rapidly iterate designs and produce functional prototypes accelerates time-to-market while maintaining quality standards.

What Role Do Quality Standards Play in the Total Cost of Ownership?

Quality considerations significantly impact the total cost of ownership, often making certified suppliers more economical despite potentially higher initial quotes due to reduced risks and improved reliability.

- Quality Management Systems and Risk Mitigation: Suppliers with robust quality management systems certified to standards like ISO 9001, IATF 16949, and AS9100D may have higher unit prices but offer greater consistency and reliability. These systems prevent expensive rework, recalls, and reputation damage that can dwarf initial price savings. For regulated industries like medical devices and aerospace, these certifications are mandatory and essential for risk mitigation.

- The True Cost of Quality Failures: The total cost of ownership includes not just the purchase price but also expenses related to quality issues. Parts that fail inspection, cause production delays, or lead to field failures incur substantial additional costs. Suppliers with proper certifications implement systematic controls that prevent these failures, ultimately providing better value despite potentially higher initial quotes.

- Alignment with Industrial Manufacturing Trends: Current industrial manufacturing trends emphasize supply chain resilience and quality assurance. Companies are increasingly valuing suppliers with strong quality systems that can ensure consistent performance. This alignment with broader industry movements makes investment in qualified suppliers strategically sound, particularly for long-term partnerships and critical components where reliability cannot be compromised.

How to Implement This Framework for Your Specific Project?

Implementing a systematic cost analysis framework requires a structured approach that considers multiple factors simultaneously. This section provides actionable steps for application to real-world projects.

1. Define Project Parameters and Requirements

Begin by clearly defining project specifications including production volume, geometric complexity, critical tolerances, material requirements, and timeline constraints. Documenting these parameters systematically ensures all relevant factors are considered during the manufacturing process selection. This foundational step prevents overlooking critical requirements that could impact cost, quality, or delivery.

2. Apply the Cost Analysis Framework

Utilize the framework presented in this article to evaluate CNC machining versus 3D printing for your specific application. Consider production volume breakeven points, complexity factors, quality requirements, and potential hybrid approaches. This analytical process should incorporate both quantitative factors (cost per part, tooling expenses) and qualitative considerations (supplier capabilities, risk factors).

3. Engage Professional Resources for Implementation

For accurate, data-based quotation analysis, leverage professional resources. Companies seeking immediate, precise quotes with design for manufacturability feedback can utilize professional online custom CNC machining services platforms. These services provide expert guidance tailored to specific project requirements, helping to validate the theoretical analysis with practical quotations and recommendations.

Conclusion

Choosing between CNC machining and 3D printing should not rely on guesswork or simplistic cost comparisons. By implementing a systematic manufacturing cost analysis that considers total cost of ownership, production volume, geometric complexity, and quality requirements, companies can make strategic decisions that reduce costs while enhancing supply chain efficiency. This disciplined approach transforms manufacturing selection from a reactive cost-cutting exercise to a strategic advantage.

H2: FAQs

Q1: Is 3D printing always cheaper for prototypes?

A: Not necessarily. While 3D printing excels at complex, low-volume prototypes with minimal setup, for simple geometries in common materials like aluminum, CNC machining can be cost-competitive even for single pieces with streamlined programming. The decision should be based on specific design, material, and timeline requirements.

Q2: What is the most overlooked cost factor when choosing between CNC and 3D printing?

A: Post-processing costs are frequently underestimated. Achieving CNC-machined surface finish or precision on 3D-printed parts often requires additional machining or hand-finishing, adding significant time and expense. Comprehensive cost analysis must account for these secondary operations.

Q3: Can 3D printing match the strength of CNC-machined parts?

A: This depends on material and process. CNC parts typically offer isotropic strength from wrought materials, while 3D-printed parts may exhibit anisotropic properties. However, with advanced metals and post-processing, some 3D-printed parts can match cast parts, though may not equal forged or machined billet materials.

Q4: How do I get an accurate quote to compare both processes?

A: Provide suppliers with detailed 3D models (STEP files), material specifications, quantities, and critical dimension tolerances. Reputable suppliers will return DFM reports highlighting potential issues and cost-saving opportunities for each process.

Q5: For new products, should I start with 3D printing then switch to CNC for production?

A: This common strategy uses 3D printing for rapid design iteration without expensive tooling, then transitions to CNC for higher volumes. However, if the design is optimized for additive manufacturing, converting to subtractive processes might be cost-prohibitive, so consider the final production method early in design.