Container dome structures are a hybrid building approach that combines two familiar elements: shipping containers and an arched, fabric or membrane cover supported by a frame. The result is a large, clear-span sheltered area that can be set up quickly compared with many conventional buildings, while still offering a defined footprint and strong edge support.

They are often discussed in the same breath as modular or relocatable buildings, but the key idea is simpler. Containers act as sturdy side “walls” and anchor points, while the dome cover creates the roofed volume in between. For a simple example of the concept in practice, references to Container Dome Structures can help clarify how these hybrid setups are typically described.

The core idea: containers as structure, dome as enclosure

A dome or arch shape is efficient because it spreads loads along the curve, rather than concentrating weight in flat spans. In many container-dome setups, the containers provide strong, rigid edges on either side of the covered space. The arch frame then bridges across the top, creating a sheltered interior without needing internal columns.

This pairing is useful when you want a large open area for equipment, vehicles, or work zones, but you also need secure side storage or a solid base for mounting doors and services.

Typical components you will see in a container dome setup

While designs vary, most container dome structures are made up of a few repeating parts:

- Shipping containers: Often placed parallel to each other to create a “bay” between them. Their steel frames provide strength and can support attachments.

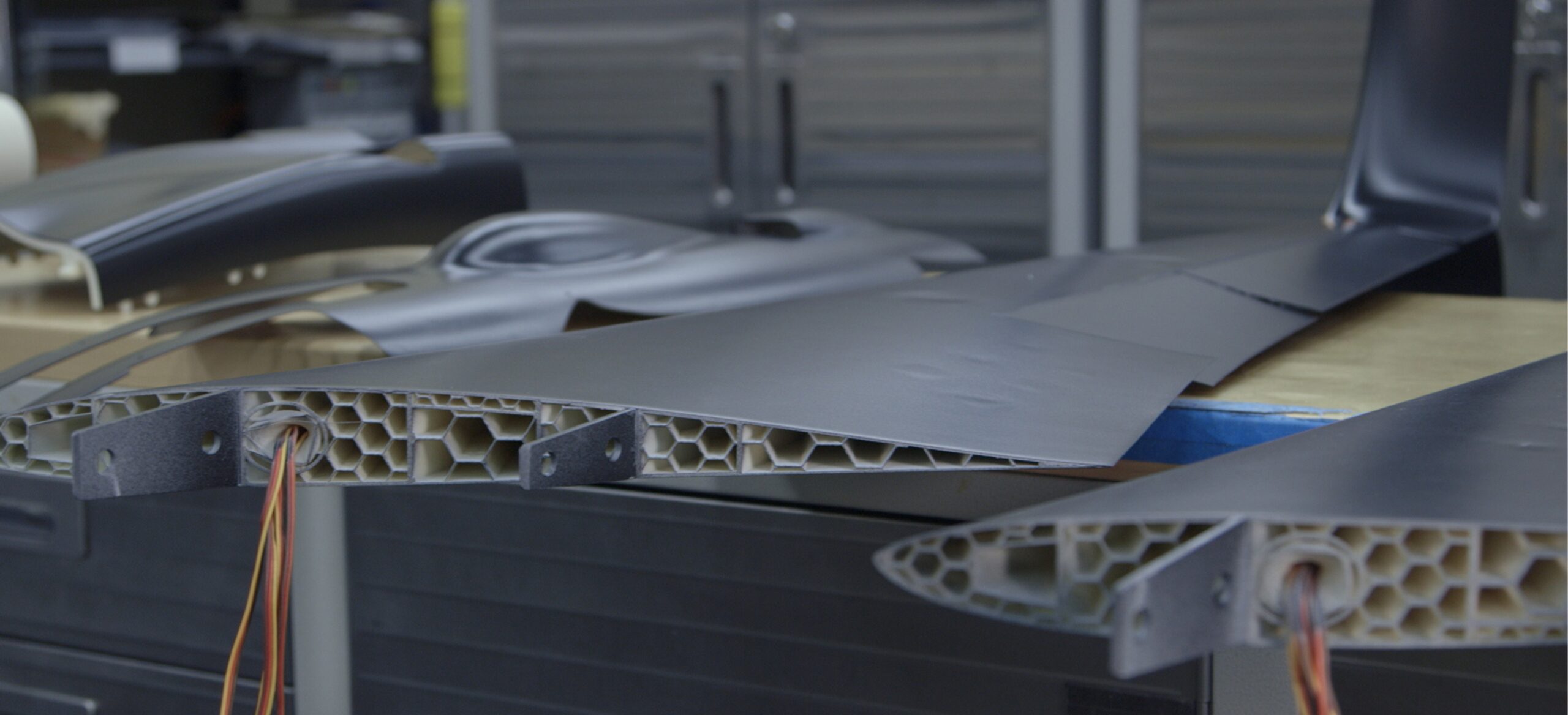

- Arch frame system: A set of curved ribs, usually steel, spaced at regular intervals. These ribs define the dome shape and provide the main support.

- Cover membrane or fabric: A tensioned outer skin that creates weather protection. The fabric choice affects durability, UV resistance, and how the structure handles wind and rain.

- Connection and bracing elements: Plates, clamps, bolts, and bracing members that stabilise the frame and help manage wind forces.

- End walls and access points: Options range from open ends to framed ends with doors, roller shutters, or personnel entry points.

Thinking in components helps because each part can be adjusted to suit the site. For example, you might prioritise access height for machinery, or select an end-wall configuration that suits workflow.

Why the dome shape is practical for storage and work areas

The arch shape creates a high internal clearance through the centre, which is valuable for storing tall items or moving equipment. It also tends to shed water effectively, since rain runs off the curved surface rather than pooling.

From a usability standpoint, clear-span space matters. Without internal posts, it is easier to park, turn, stage materials, or set up temporary work zones. For operations that change layout frequently, that flexibility can be more important than perfectly finished interior walls.

How container placement influences the interior space

The distance between the two containers largely determines the usable width of the covered area. Container height also affects side clearance and how the dome meets the edges.

In some configurations, the containers do more than act as edges. They can be used as lockable storage, tool rooms, or site offices, which keeps the central covered area free for operations. This dual-purpose layout is a major reason the concept is attractive for remote sites and temporary projects.

What “fast and modular” really means in practice

When people say container dome structures are fast, they usually mean fewer traditional building steps. There is typically less reliance on complex wall framing, and the repeating arch components are designed for efficient assembly.

Modular does not always mean “no planning,” though. You still need to consider:

- Site access: Room for delivery and placement of containers and frame parts.

- Ground conditions: A stable, well-drained base reduces movement and helps long-term performance.

- Wind exposure: Curved structures handle loads differently than flat roofs, but wind forces still matter.

- Anchoring and fixing details: The structure must be secured appropriately for its location and use.

A realistic view is that the system can be simpler than many conventional builds, but it still benefits from careful site planning.

Weather performance: wind, rain, heat, and condensation

Most interest in these structures comes from their ability to provide large-area shelter. Rain protection is typically strong when the cover is properly tensioned and the site has adequate drainage.

Heat and condensation deserve special attention. Like many large shelters, a covered space can trap warm air, and temperature swings can encourage condensation on surfaces. Ventilation choices, end-wall design, and how the structure is used (for example, wet equipment storage versus dry goods) all influence comfort and moisture management.

Where container dome structures tend to fit best

These structures are often used when you need a lot of covered space quickly, especially where traditional construction is slower, costlier, or less practical. Common use cases include:

- Equipment and machinery storage

- Agricultural storage and operational bays

- Remote project sites needing secure side storage plus sheltered working space

- Temporary logistics hubs or staging areas

- Workshops where clear internal movement is important

The best fit is usually where function and adaptability matter more than interior finishing, and where the ability to reconfigure or relocate has real value.