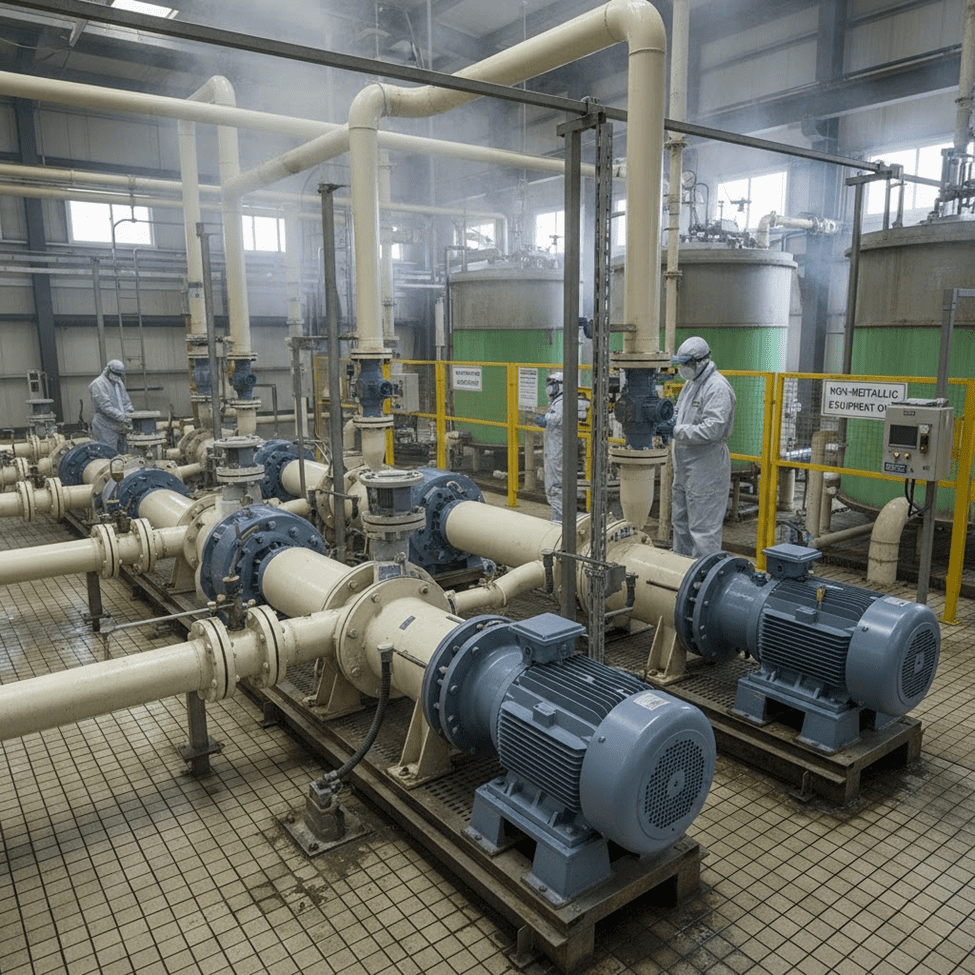

In chemical industries and industrial plants, handling corrosive fluids safely and efficiently is a major challenge. Choosing the right pump is critical because using unsuitable pumps can lead to frequent breakdowns, safety hazards, and high maintenance costs. Non-metallic pumps are becoming increasingly popular in India for such applications due to their ability to withstand harsh chemicals without corroding. Selecting the correct pump not only ensures smooth operations but also protects the investment and maintains plant productivity over time.

Superior Corrosion Resistance

One of the biggest advantages of non-metallic pumps is their excellent resistance to chemical degradation. Unlike metallic pumps that may rust, pit, or wear quickly when exposed to acids, alkalis, or other aggressive chemicals, non-metallic materials such as polypropylene, PVC, and PVDF provide a strong barrier against corrosion. This makes them ideal as corrosion-resistant pumps for industries dealing with highly reactive substances. Many Non-Metallic Pump Manufacturers in India design these pumps specifically to meet the demands of harsh chemical environments. For example, in chemical processing plants, these pumps can handle strong acids or chlorine-based solutions without suffering damage. The durability of non-metallic pumps ensures that they continue to perform reliably for a long time, reducing the risk of unexpected failures and increasing operational efficiency in industrial processes.

Reduced Maintenance and Downtime

Non-metallic pumps are easier to maintain compared to their metallic counterparts. Their resistance to corrosion and chemical wear means they rarely require frequent repairs or replacements. In Indian industrial setups, where downtime can lead to significant production losses, this reliability is especially valuable. Maintenance supervisors can spend less time fixing pump issues, allowing the plant to operate smoothly. Furthermore, fewer repairs mean lower labour costs and minimal interruption in the workflow. Chemical processing pumps made from non-metallic materials provide consistent performance over long periods, making them a practical choice for plants that cannot afford frequent downtime or high maintenance expenses.

Lightweight and Easy Installation

Another practical advantage of non-metallic pumps is their lightweight construction. Compared to heavy metallic pumps, these pumps are much easier to handle during installation, relocation, or replacement. Plant engineers can save time and reduce physical strain during setup. Their lighter weight also reduces the need for strong structural supports, which can lower installation costs. In Indian industries where space and resources may be limited, lightweight corrosion-resistant pumps provide a convenient solution, making it easier to implement new systems or retrofit existing setups without heavy machinery or additional structural modifications.

For industries handling aggressive chemicals, using non-metallic pumps for corrosive fluids like the NKP Series ensures reliable operation, long service life, and minimal maintenance in demanding environments.

Cost-Effectiveness Over Time

Although non-metallic pumps may have slightly higher initial costs than standard metallic pumps, they are highly cost-effective in the long run. Their long-lasting corrosion resistance reduces the need for frequent replacements and costly repairs. Downtime is minimized, which further improves plant efficiency and productivity. For Indian industrial plants dealing with corrosive fluids, investing in non-metallic chemical processing pumps can result in significant savings over time. The total cost of ownership is often lower compared to metallic pumps, making them a smart financial choice for facilities that want to balance performance, reliability, and budget.

Versatility in Applications

Non-metallic pumps are highly versatile and can be used across a wide range of industries and processes. They handle acids, alkalis, solvents, and other corrosive liquids safely, making them suitable for chemical plants, wastewater treatment units, and manufacturing facilities. Industrial pumps made from non-metallic materials allow plants to standardize equipment for different fluids, reducing complexity and inventory costs. Their adaptability ensures that Indian industries can rely on a single pump type for multiple applications without worrying about corrosion-related failures, offering both operational flexibility and peace of mind.

Conclusion

Non-metallic pumps offer corrosion resistance, low maintenance, lightweight handling, cost savings, and versatile applications, making them ideal choices.